Car Washes and Lube Shops - Waste Oil Boiler and Heater Installations

These car wash and lube shops are saving thousands of dollars every year in heating costs and have eliminated their used oil disposal expenses. They heat their shops and car wash water with boilers fired by waste oil recycled on site from their own lube shop. Utility bill savings for heat and car wash hot water typically pay for a new system in 24 – 36 months. With minimal maintenance, waste oil burning boilers run for decades. Radiant floor heat is cost-effective in new facilities. Unit heaters are cost-effective for new and existing lube shops.

Rainford's Lube-Oil

Yakima, Washington

Equipment: Columbia WL-60 waste oil fired boiler with Firelake/Shenandoah B-10 burner

Project: Supply and install radiant floor heating, frost pads, and hydronic heaters in lube shop and heat hot water for car wash. Radiant floor heat and frost pads melt snow and ice and help dry up standing water to reduce slips and falls in the lube shop.

Wash & Lube Time

Bend, Oregon

Equipment: Columbia WL-60 waste oil-fired boiler with Firelake/Shenandoah B-10 burner.

Project: Supply and install waste oil-fired boilers to reuse all used automotive oils onsite. Waste oil is recycled in their new boiler to heat the facility and heat the water for the car wash.

Classy Chassis - Xpress Lube & Car Wash

Lakewood, Washington

Equipment: Columbia WL-60 waste oil fired boiler with Shenandoah B-10 burner

Project: Supply and install radiant floor heating for 3-bay oil change shop, hot water for car wash, and snow and ice melt outside of bay entries.

Auto Spa

Yakima, Washington

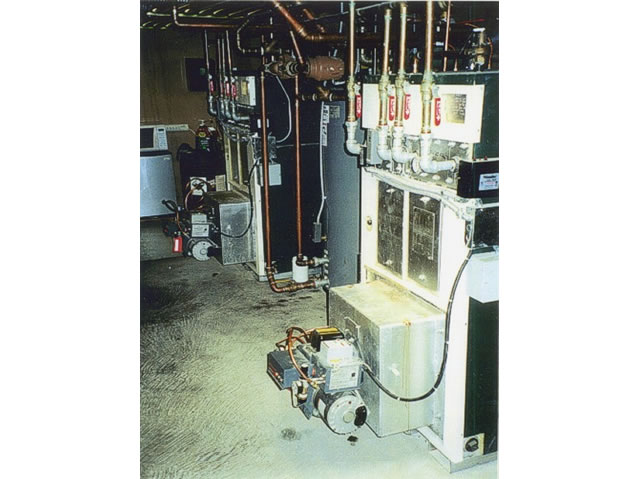

Equipment: 2 Columbia WL-60 waste oil fired boilers with Firelake/Shenandoah B-10 burners

Project: Supply and install radiant floor heat for two bay oil change shop and hot water for two bay car wash.